Lots of helpers this weekend; who says you can't look stylish while building an airplane?!

(After these 2 pics were taken we moved the right wing to the other side of the rack to allow the top skins to fit over the racks)

Our good friends the O'Connors came over for the day, and Chris & I got to work mashing rivets on the left wing skeleton.

I shot (3x gun 45 psi), he bucked

I can't believe we haven't had to drill out a rivet!

Main rib/main spar rivets complete!

Or as Chris is clearly thinking, that's right ladies, we are that good.

Next we threw on the left rear spar and squeezed some rivets.

Complete!

Left wing skeleton, never to come apart again.

I started measuring & cutting the right wing walk doubler from the AS3-025 aluminum sheet provided by Vans. Simple straight aviation snips did the trick.

I then lined up the doubler per the manual & did the initial match drilling, clecoing it right to the workbench. This is a technique they taught at the EAA SportAir Workshop I went to; not sure if I would have thought to try it otherwise.

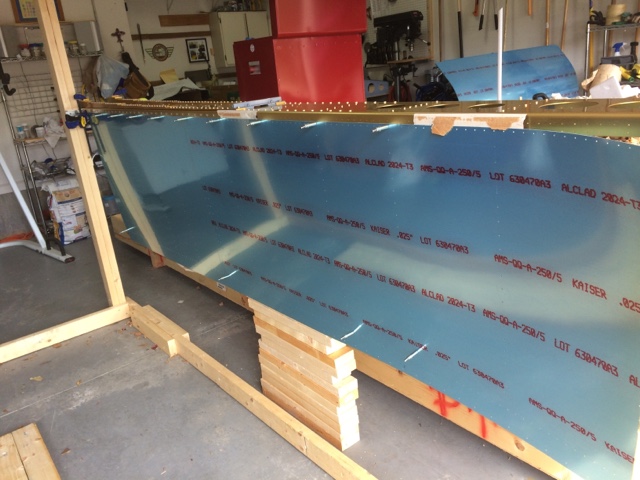

Chris was busy finishing the clecoing of the right top skins and starting match-drilling.

Right wing walk doubler complete!

Chris's son Naish needed some man time and joined us in the garage. Nothing like power tools to make a guy of any age smile.

Right wing 25% match-drilled!

Next up will be clecoing the rest of the skins on, finishing the match drilling, catching up the left wing, deburring, and then moving on to leading edge assemblies.

All of a sudden we have more finished parts! And better yet our friends will be back in 2 weeks. Life is good.

Wings: 6 hrs